Our Services

3-Gen are specialists in high voltage cable engineering. Our team of Project Managers, Engineers, Jointers, Technicians, and support staff deliver comprehensive services for the design, supply, installation, jointing, testing, and commissioning of high voltage cable systems. We work across a range of voltages and industries, offering tailored solutions to meet the specific requirements of each project.

We maintain a directly employed, fully qualified team of Jointers and Technicians. This allows us to deliver a consistent standard of workmanship using in-house resources wherever possible, ensuring quality, safety, and reliability across every stage of delivery.

XLPE/Fluid Filled Cable Jointing

With over 35 years of specialist experience, 3-Gen has established itself as a trusted name in fluid-filled cable jointing and repair, working on systems from 33kV up to 132kV. Our team delivers high-quality, reliable solutions across a wide range of cable technologies, including:

Fluid-filled cable jointing and transition joints.

XLPE cable joinings.

Joint bay refurbishments

High-pressure fluid and oil plumbing

Sleeve repairs and oil leak containment

Link box refurbishment

Pilot cable jointing

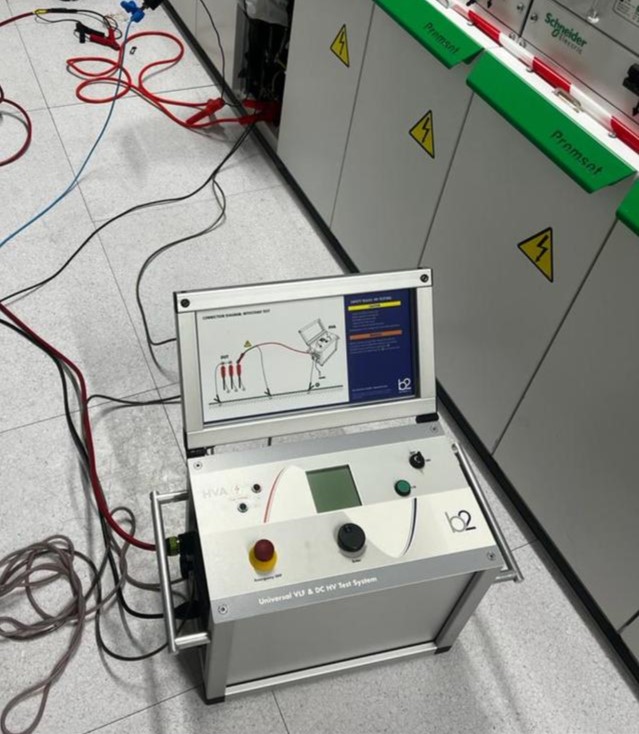

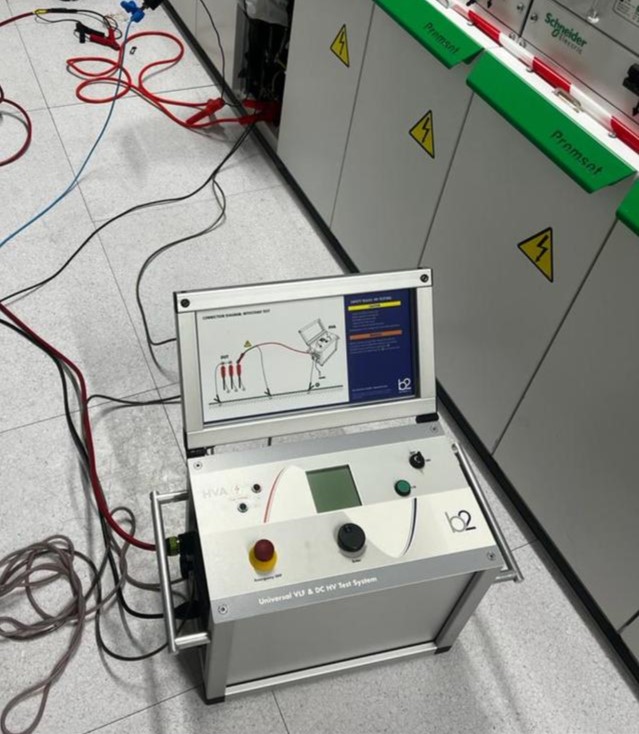

Fault Finding/Testing

3-Gen offer VLF (Very Low Frequency) testing as part of our commissioning and cable condition assessment services. Using calibrated, industry-approved equipment, we carry out both withstand and diagnostic tests on XLPE and EPR cable systems up to 132kV. VLF testing is a safe and effective method for detecting insulation degradation and partial discharge, giving clients peace of mind that their cable systems are reliable and ready for energisation.

IR Testing

3-Gen provide Insulation Resistance (IR) Testing to assess the health of cable insulation. Using high-quality megohmmeters, we test both new and existing installations to determine insulation integrity. IR testing is essential during commissioning, and also plays a key role in identifying deterioration in ageing or damaged cables—helping operators take preventative action before faults occur.

Sheath Testing

To protect against water ingress and subsequent insulation failure, we carry out DC sheath testing and sheath fault location. These tests identify weaknesses or defects in the cable sheath, which can lead to long-term system issues if left unresolved. Our precise location techniques support efficient repair planning and form an important part of effective asset management for HV networks.

Cable Containment and Cleating

We offer complete containment and cleating solutions to ensure that high voltage cables are installed safely and securely. Our team installs ladder racks, cable trays, and high-strength cleats designed to restrain cables under electrical fault conditions and mechanical stress. Correct containment is essential for system longevity, compliance, and the safe management of dynamic electrical forces.

Link Boxes

3-Gen supply, install, and refurbish link boxes used within HV cable bonding systems. We support all configurations—including screened, insulated, and solidly bonded systems—and carry out earth continuity testing and routine maintenance. Our services help to ensure safe bonding arrangements, reduce the risk of induced voltages, and maintain long-term system performance.

Pilot Jointing

Our experienced team carries out pilot cable jointing to support control, protection, and communication systems in high voltage networks. We work with a wide range of pilot cable types and core arrangements, ensuring correct terminations and long-lasting reliability. Effective pilot jointing is essential for the dependable operation of auxiliary systems, including remote signalling and protection relays.